Mesotherapy is a non-surgical cosmetic treatment that involves injecting small amounts of medication or natural substances into the middle layer of the skin, known as the mesoderm. This technique is widely used for rejuvenation and skin tightening, hair loss treatment, and to reduce the appearance of cellulite. One of the crucial components of mesotherapy is the needle used for injecting the solution. In this article, we will discuss the needle size, usage, and production process of mesotherapy needles.

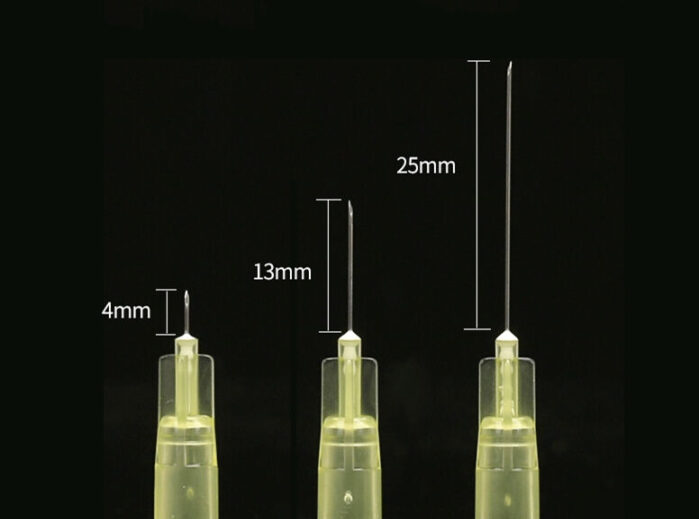

Needle Size

Mesotherapy needles come in various sizes, ranging from 4mm to 13mm in length and 30 to 32 gauge in thickness. The gauge represents the diameter of the needle, with the smaller number indicating a thicker needle. The size of the needle is chosen based on the location of the injection and the viscosity of the solution. The thinner needles are usually used for facial treatments, while the thicker needles are suitable for body treatments.

Usage

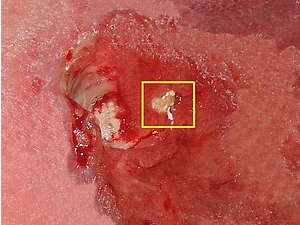

Mesotherapy needles are used to inject a mixture of vitamins, minerals, amino acids, and hyaluronic acid into the mesoderm, the middle layer of the skin. The injection process creates tiny punctures in the skin, which stimulates the production of collagen and elastin fibers. This leads to a firmer and more youthful-looking skin.

The procedure begins with a thorough cleansing of the skin, followed by the application of a topical anesthetic cream. After the skin is numb, the mesotherapy solution is prepared and loaded into the syringe. The needle is then inserted into the skin at a 90-degree angle and the solution is injected in small amounts while the needle is slowly withdrawn. The procedure takes around 30 minutes to complete and requires no downtime.

Production Process

The production process of mesotherapy needles involves several steps. The first step is the manufacturing of the needle itself. The needles are made from medical-grade stainless steel and are manufactured using a process called swaging. Swaging is a process where the needle is made by compressing and shaping the stainless steel into the desired shape and size.

After the needle is manufactured, it is then coated with a lubricant, such as silicone or Teflon. This coating helps the needle to glide smoothly through the skin during the injection process. The needle is then sterilized to ensure that it is free from any harmful bacteria or viruses.

The final step in the production process is the assembly of the needle and syringe. The needle is attached to a plastic hub, which is then attached to the syringe. The syringe is filled with the mesotherapy solution, and the needle is ready to be used.

In conclusion, mesotherapy needles are an essential component of the mesotherapy treatment. The size of the needle is chosen based on the location of the injection and the viscosity of the solution. The procedure involves injecting a mixture of vitamins, minerals, amino acids, and hyaluronic acid into the mesoderm, which stimulates the production of collagen and elastin fibers. The production process of mesotherapy needles involves several steps, including manufacturing, coating, sterilization, and assembly.