Blunt Tip Cannulas

Blunt tip cannulas are specialized needles used in cosmetic procedures such as dermal filler injections. Unlike traditional needles, blunt tip cannulas have a rounded, dull tip that minimizes tissue trauma and reduces the risk of bleeding and bruising. The production process for blunt tip cannulas typically involves the following steps:

Material selection

Blunt tip cannulas are typically made from medical-grade stainless steel or plastic. The material used must be strong, durable, and able to withstand repeated use and sterilization.

Cutting and shaping

Once the material has been selected, the next step is to cut and shape the cannula. This is typically done using a precision cutting machine that is programmed to produce cannulas of a specific size and shape. The machine may use a variety of cutting tools, such as diamond blades or lasers, to create the cannula.

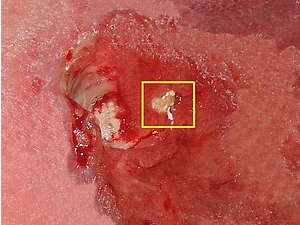

Grinding and polishing

After the cannulas are cut and shaped, the next step is to grind and polish the tips to a smooth, rounded finish. This not only improves the aesthetic appearance of the cannula but also helps to reduce the risk of tissue damage or irritation during use.

Sterilization and packaging

The final step in the production process is to sterilize the cannulas and package them for distribution. Sterilization typically involves exposing the cannulas to high heat or chemicals to kill any bacteria or viruses that may be present on the surface of the cannula. Once the cannulas are sterilized, they are typically packaged in sterile containers and shipped to hospitals and medical facilities for use in cosmetic procedures.

Meso Needles

Meso needles are small, fine needles used in mesotherapy, a cosmetic procedure that involves injecting vitamins, minerals, and other nutrients into the skin to improve its appearance. The production process for meso needles typically involves the following steps:

Material selection

Meso needles are typically made from medical-grade stainless steel or titanium. The material used must be strong, durable, and able to withstand repeated use and sterilization.

Cutting and shaping

Once the material has been selected, the next step is to cut and shape the needle. This is typically done using a precision cutting machine that is programmed to produce needles of a specific size and shape. The machine may use a variety of cutting tools, such as diamond blades or lasers, to create the needle.

Grinding and polishing

After the needle is cut and shaped, the next step is to grind and polish the tip to a smooth, sharp finish. This is important because it ensures that the needle can easily penetrate the skin and other tissues without causing excessive trauma.

Sterilization and packaging

The final step in the production process is to sterilize the needle and package it for distribution. Sterilization typically involves exposing the needle to high heat or chemicals to kill any bacteria or viruses that may be present on the surface of the needle. Once the needle is sterilized, it is typically packaged in a sterile container and shipped to hospitals and medical facilities for use in mesotherapy procedures.

In conclusion, the production process for blunt tip cannulas and meso needles is a complex and multi-step process that requires careful attention to detail and quality control to ensure that the needles are safe and effective for use in cosmetic procedures. By selecting high-quality materials and using precision cutting and grinding machines, manufacturers can produce needles that are reliable, efficient, and safe for use in a variety of cosmetic procedures.