Platelet-rich plasma (PRP) therapy is a popular treatment for a variety of conditions, including arthritis, sports injuries, and hair loss. PRP therapy involves extracting a small amount of blood from the patient, processing it in a PRP tube or kit, and injecting the resulting platelet-rich plasma into the affected area. In this article, we will discuss PRP tubes and kits, their species and types, usage, production process, distribution of industry chain, manufacture plant quantity and capacity, as well as their future development.

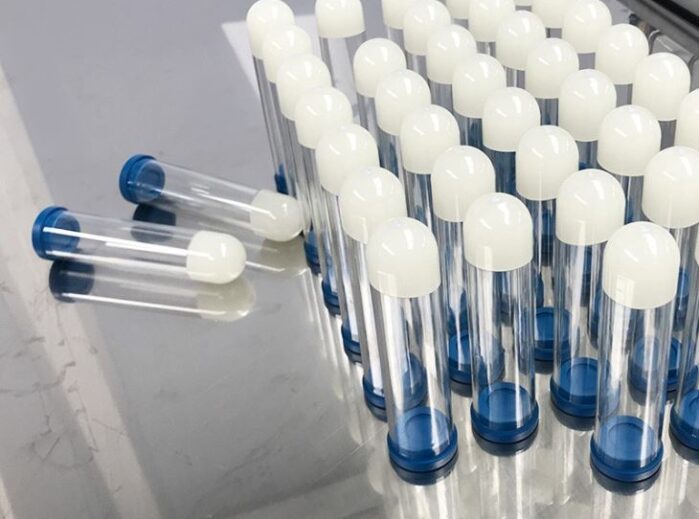

PRP Tube and Kit

A PRP tube is a sterile, single-use tube designed for the collection and processing of whole blood into PRP. It contains anticoagulant agents and a separation gel that separates the red blood cells from the plasma during centrifugation. A PRP kit, on the other hand, is a kit that contains all the necessary components for the collection, processing, and injection of PRP. It typically includes a PRP tube, a centrifuge, and a syringe for injection.

Species and Types

PRP tubes and kits can be classified into two species: manual and automated. Manual PRP tubes and kits are less expensive and require more manual labor, as the blood must be manually transferred from the collection tube to the processing tube. Automated PRP tubes and kits, on the other hand, are more expensive but are more convenient to use, as they automate the blood transfer process.

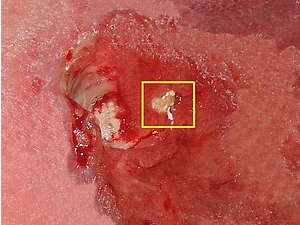

Usage

PRP therapy is used to treat a variety of conditions, including sports injuries, osteoarthritis, and hair loss. It is also used in cosmetic treatments, such as skin rejuvenation and wrinkle reduction. PRP therapy works by promoting the body’s natural healing process, as platelets contain growth factors that stimulate tissue repair and regeneration.

Production Process

The production process of PRP tubes and kits involves several steps, including the manufacturing of the tube or kit components, assembly, and sterilization. The tube or kit components, such as the tube, separation gel, and anticoagulant agents, are manufactured by suppliers and sold to PRP tube and kit manufacturers. The manufacturers assemble the components into the final product and sterilize them using gamma irradiation or ethylene oxide gas.

Distribution of Industry Chain

The PRP industry chain is composed of several stages, including raw material production, component manufacturing, tube and kit assembly, and distribution. Raw materials, such as tubes, separation gel, and anticoagulant agents, are produced by suppliers and sold to component manufacturers. Component manufacturers produce the tube and kit components and sell them to tube and kit assembly plants. Tube and kit assembly plants assemble the components into the final product and distribute them to healthcare providers.

Manufacture Plant Quantity and Capacity

The manufacture plant quantity and capacity of PRP tubes and kits vary depending on the company and location. Many of the largest PRP tube and kit manufacturers are based in Asia, particularly in South Korea and China. According to a recent report by Grand View Research, the global PRP market was valued at $410.9 million in 2020, with North America accounting for the largest share of the market. The report also projects that the market will continue to grow in the coming years, driven by increasing demand for regenerative medicine and the growing prevalence of chronic diseases.

Future Development

The future development of PRP tubes and kits is focused on improving the efficiency and convenience of the PRP therapy process. New technologies, such as point-of-care systems, are being developed to enable the rapid processing and injection of PRP. The use of nanotechnology and biomaterials is also being explored to enhance the therapeutic properties of PRP. Additionally, the development of personalized PRP therapy, where the concentration of platelets is tailored to the patient’s specific